Artificial Intelligence: The future of sheet metal starts today

What is artificial intelligence (AI)? The concept is widely discussed and has become highly important in recent years.

But what is it all about? In simple terms, it refers to systems or machines that imitate human intelligence in performing tasks and can improve iteratively based on the information that they gather.

From this initial definition AI is no more than a tool that can be applied to endless areas and products. It is not itself a software system, but it can be added to different software packages to improve, accelerate, and predict decision-making, through the implementation of patterns-based models.

AI refers to systems or machines that imitate human intelligence in performing tasks and can improve iteratively based on the information that they gather.

To take a simple example, imagine that you arrive at work between 8:50 AM and 9:15 AM and set your mobile phone to silent mode as you go through the door on five consecutive days. On the sixth you get a message saying “it looks as if you need to mute your device in the same location at 9 AM from Monday to Thursday. Do you want this to be done automatically?” You have not entered any instructions on your phone: it has detected the pattern on its own, has learned and has suggested that this be done automatically. This is IA applied to daily life.

How can this be applied to metal possessing? AI enables software systems reduce uncertainty based on data generated at each different level of a sheet metal cutting service. We can shift from unconnected systems in which the operator collects information and transfers it on a physical or digital medium to the rest of the areas of the company to a situation in which all processes are digitized and interconnected, so that a huge amount of data is obtained. This eliminates no add value tasks and guarantees that data will be properly recorded in terms of form and time, avoiding bias, differences in criteria and subjectivity.

The resulting data can then be analysed using IA so that systems can learn and anticipate events, considering a large number of variables. This can be applied in many areas, from predictive machine maintenance to choosing the requests for quotes which are of most interest to the company at a given time and solving bottlenecks in production. The possibilities are endless.

We can move to a situation where all processes are digitized and interconnected, resulting in a huge amount of data.

But the first step is to have machines and systems with the software required to ensure the reliability of the data obtained. One of the dangers of using AI is applying it to poor-quality data, i.e. to data sources that provide incorrect measurements with noise, information losses, etc. This leads to incorrect conclusions and results in turn in wrong decisions being made. There is no point in setting up AI if the software is not capable of processing data correctly. There is therefore a need for machines which are not only faster and more accurate but also able to interconnect with third-party software, process, assure and issue high-quality information, detect anomalies, fill gaps in data, correct wrong measurements and issue alerts concerning potential malfunctions in sensors or processes, while always guaranteeing that data will be delivered. That is why the IoT has turned machines into high value-added digital products.

Who would have believed 10 years ago that mobile phones would become computers with a data processing capability greater than the most powerful computers of just a few decades ago, and that the AI used in their software would make life easier for us, enabling us to use them to monitor our health, make payments at businesses and make decisions on business matters wherever we may be.

Similarly, machines and automation systems in the sheet metal processing industry can help to speed up decision-making. The first step is to have machines capable of connecting to one another and to other systems, and of providing reliable data.

There is therefore a need for machines which are not only faster and more accurate but also able to interconnect with third-party software, process, assure and issue high-quality information, detect anomalies, fill gaps in data, correct wrong measurements and issue alerts concerning potential malfunctions in sensors or processes, while always guaranteeing that data will be delivered.

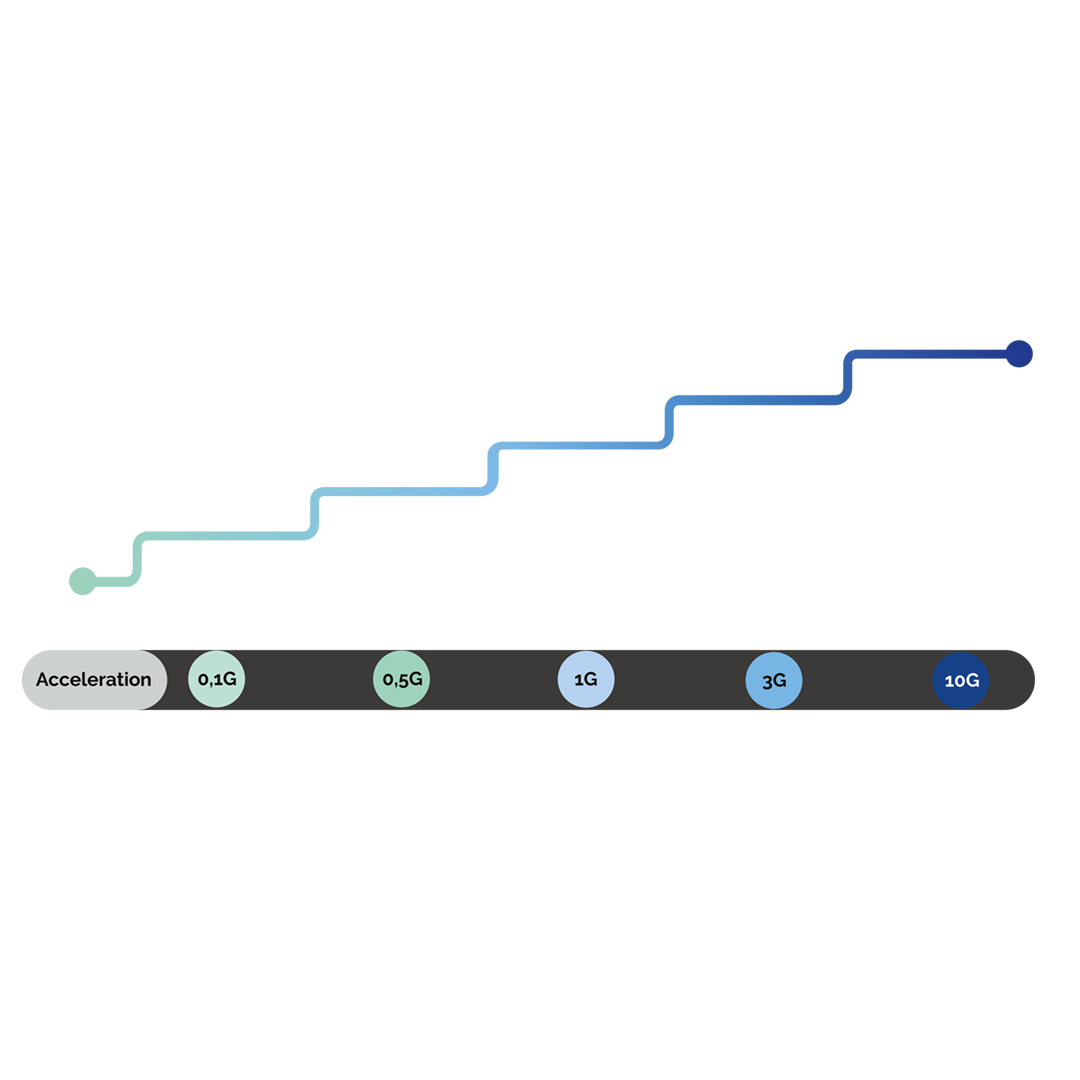

The constant spin concerning the importance of AI tools to which we are subjected suggests that anyone can implement them and immediately obtain improvements in performance and decision-making. However, that is not entirely true: a certain level of digitization is required. Organisations need to reach Challenger level on the scale in the Digital Maturity Model (DMM) by Kurago before they can even think of applying AI. There must be processes in the different areas of the company and software that can be used to extract data. It must also be established beforehand what the relevant indicators for each business are. Only then is it possible to analyse data in such a way as to draw conclusions that can speed up decision-making. Once an organisation reaches that level it can think about applying AI which can facilitate decision-making in specific circumstances in its business.

AI can be a powerful tool if it is used in a context where there is sufficient digital maturity but is of no use if the data available is of poor quality or if it is not known what indicators are most relevant to the business. It is essential to know what the company’s digital maturity level is before making any decision as to what steps to take to increase digitization.